TECHNICAL SPECIFICATION

ONELAY CONDUCTOR | HEAT RESISTANT AND FLAME RETARDANT - LEAD FREE

Does not Propagate Flame and Fire

Colors :

Entire cable has white base and a double strip of red or yellow or blue or black or green or grey running along the cable length

Data Chart : Cable Design Parameters

| Nominal Cross Sectional Area (Sq. mm) | Nominal Insulation Thickness (mm) | Number *Nominal Dia. of Strands | Approx. Overall Diameter (mm) | Max. DC ConductorResistance at 20°C(Ω/km) | Current Rating (Amps) Casing | Current Rating (Amps) Concealed |

|---|---|---|---|---|---|---|

| 1 | 0.7 | 37/0.20 | 2.6 | 19.5 | 12 | 11 |

| 1.5 | 0.7 | 37/0.22 | 3.0 | 13.3 | 16 | 15 |

| 2.5 | 0.8 | 61/0.22 | 3.6 | 7.98 | 23 | 19 |

| 4 | 0.8 | 61/0.30 | 4.1 | 4.95 | 30 | 26 |

*Conductor as per IS 8130. # Traditionally bunched conductor

APPLICATION

Wiring in all installations where fire safety is of utmost importance like schools, theaters, commercial complexes, apartments, high rise buildings, laboratories, etc.

TECHNICAL DATA

Voltage Grade :

Up to and including 1100V

Conductor :

Thin strands of electrolytic copper are multi-drawn

for uniformity of resistance, dimension and flexibility.

The drawn strands are uni-laid with high precision and compacted.

Thus forming a perfectly circular conductor which enables reduction

in overall diameter for space saving in high density wiring.

Conductor Speciality :

The strands do not get cut when stripping the insulation. The conductor offers perfect contact at pins, terminals and sockets. Thus, eliminating spot heating and sparking.

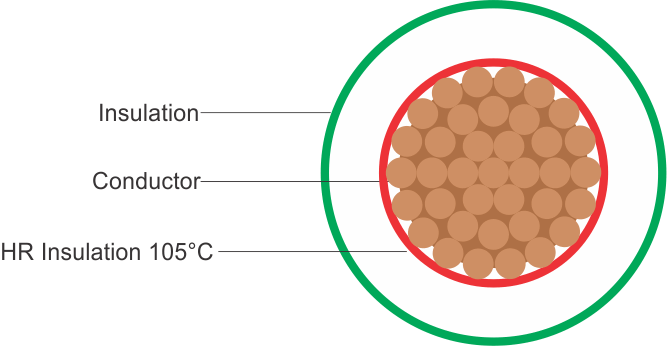

Insulation :

Specially formulated grade of Heat Resistant & flame retardant compound is used. The insulation does not burn readily. It does not melt and drip, non-toxic.

Insulation Confirmity :

IS 5831, Type - HR 105°C & FR - 90°C

Marking :

The cables are printed with marking of “VIHAN ONELAY (UNILAY CONDUCTOR) HR - FR” upto 4 Sq. mm

Packing :

90 mtr. coils packed in “STACKPAK” with protective Cartons.

PROPERTIES

Limited Oxygen Index as per ASTM - D 2863 - >32%

Limited Temperature Index as per ASTM - D 2863 - > 250°C

Smoke Density (Light Absorption) as per ASTM - D 2843 - < 10%

Acid Gas Generation as per IEC - 60754 - 1 - < 5%